Sewer Joint Grout Sealing

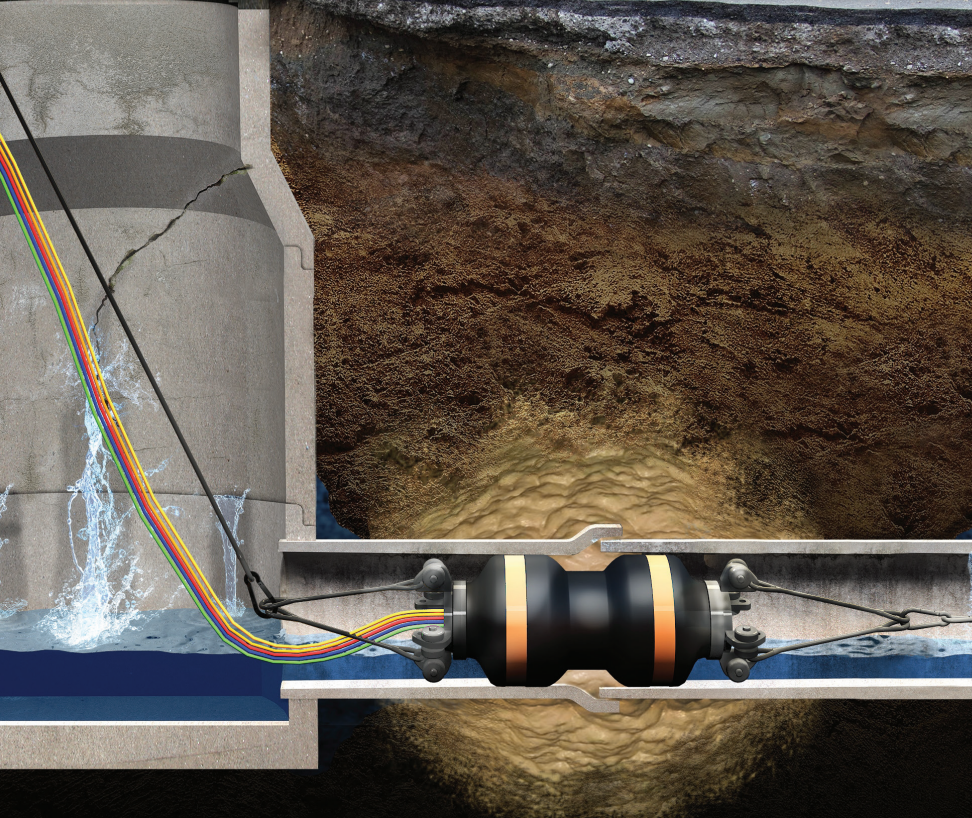

The mainline grouting process begins by air-testing joints to determine grouting requirements. If a joint fails an air test, a packer containing the grout is inserted into the line through the manhole. After centering on the joint, the packer is inflated, and grout is injected through the joint connection. The grout creates a hard, impermeable gel around the outside of the pipe. The packer is then deflated, and pulled back for camera inspection, scraping the remaining gel ring leaving 100% flow capacity in the pipe.

Chemical grouting in sewer systems intends to seal leaks and stop infiltration and exfiltration. Groundwater infiltration into sanitary sewers increases flow levels and puts more pressure on treatment plant facilities. This may eventually lead to unnecessary construction of larger volume treatment plants, where simple grouting procedures would have sufficed.

Infiltration and Salinity Control

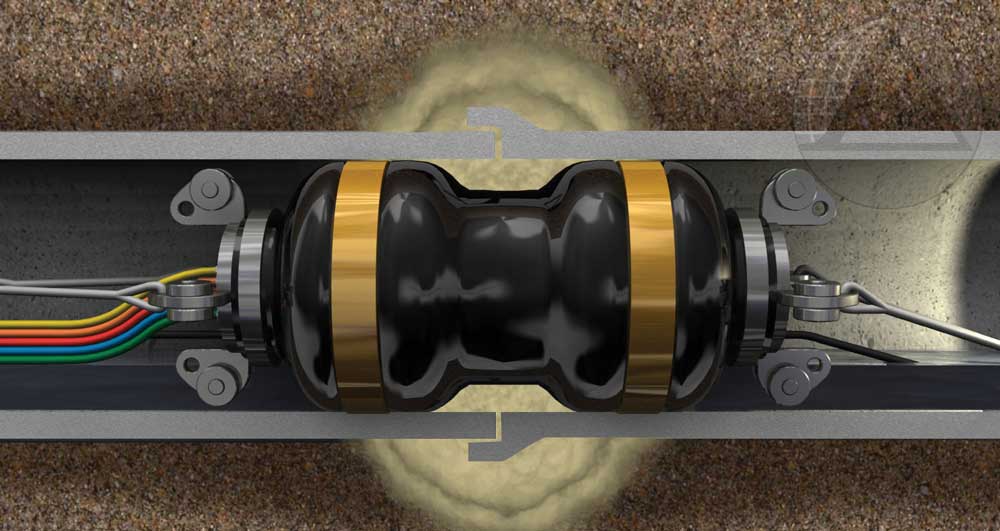

Infiltration in sewers causes soil erosion, washing fine soil particles into the sewer system. This soil erosion leads to sinkholes, undermining the pipe supports. As a result, the pipe’s structural integrity is endangered due to the washout of backfilling material. To resolve this problem, the soil stabilization process is often used.

Chemical grouts do not stop leaks simply by patching joints and cracks. Instead, grouting chemicals are forced through the joints and cracks into the surrounding soil to form a waterproof mass that cannot be pushed back into the sewer system.

Soil Stabilization

Soil stabilization works by pumping grout into the soil surrounding the outside of the pipe. The grout quickly forms a strong, permanent seal around the pipe, holding it in place, and reestablishing the density of the eroded soil.

It is important to act quickly to stabilize soil where infiltration has occurred. Pipes showing infiltration in Stage 1 (see diagram below), are good candidates for soil stabilization. If these problems are not treated, however, the pipe will eventually degrade to Stage 3 Failure (below). Treating infiltrating pipes early with soil stabilization is the safest and most economical way to solve your infiltration problems.